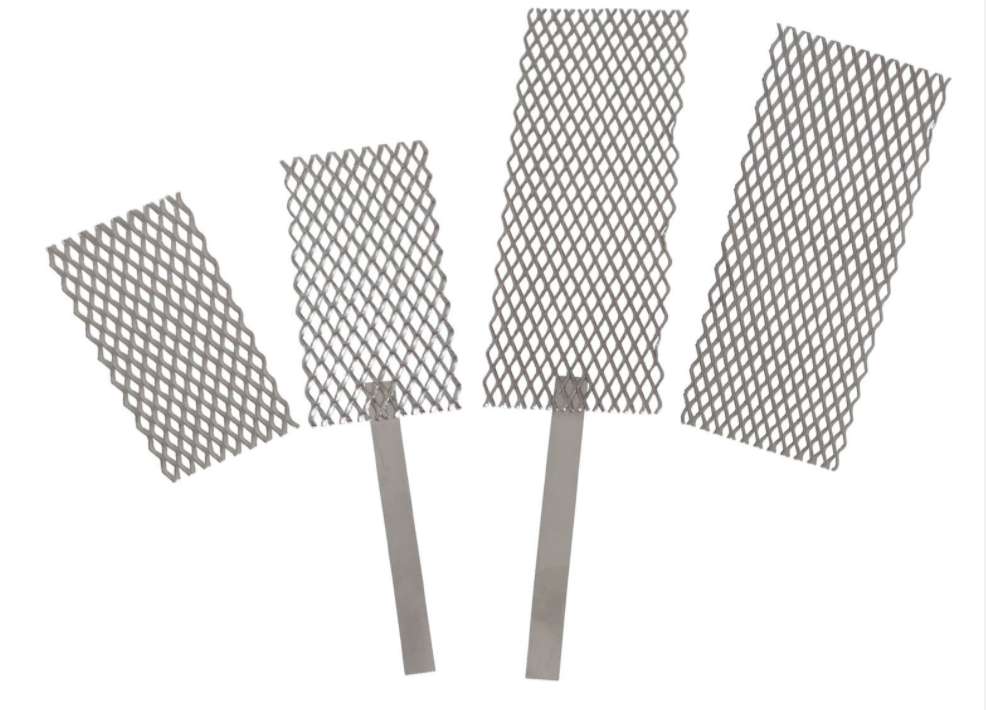

Titanium-plated anode, commonly known as DSA. Also known as DSE . It is a new type of insoluble anode material developed in the late 1960s.

DSA-coated titanium anodes are used in the following fields: chlor-alkali industry, chlorate production, hypochlorite production, perchlorate production, persulfate electrolysis, electrolytic organic synthesis, electrolytic extraction of non-ferrous metals, electrolytic production of silver catalysts , copper electrolysis to produce aluminum foil, electrolytic mercury oxide recovery, water electrolysis, chlorine dioxide production, hospital wastewater treatment, electroplating plant cyanide wastewater treatment, domestic water and food utensils disinfection, power plant cooling circulating water treatment, wool spinning factory dyeing and finishing wastewater treatment , industrial water treatment, electrolytic production of acid-base ionized water, copper galvanizing, rhodium plating, palladium plating, gold plating, lead electroplating, electrodialysis seawater desalination, electrodialysis production of tetramethylammonium hydroxide, electrolytic molten salt, battery production, cathode Protection, negative electrode foil production, aluminum foil anodizing, etc.

It is widely used in chemical industry, metallurgy, water treatment, environmental protection, electroplating, electrolytic organic synthesis and other fields.

The performance characteristics of DSA-coated titanium anodes are as follows:

①Low anode overpotential: Chlorine evolution DSA is used for electrolysis of chlorine-containing brine solution, and oxygen evolution DSA is used for electrolysis of H2SO4HNO3 and brine solution. The overpotential of the chlorine-evolution and oxygen-evolution anodes is lower than that of other anodes, and the side reactions are significantly reduced, which can be used stably for a long time under low electrolysis voltage, achieving the effect of energy saving and cost reduction.

②Long service life: Graphite and lead alloy anodes can be replaced after a few to one years of use, while DSA anodes can be used for more than 6 years, or even as long as 10 years. The comprehensive economic service life is significantly improved and the benefits are significantly improved.

In recent years, in the application of surface treatment industry, new trends have emerged in DSA-coated titanium anodes, such as adding certain nanomaterials to the coating to improve the electrocatalytic activity of DSA anodes, and in some specific solutions, by adjusting The oxygen evolution potential of DSA coating can inhibit the production of certain impurity ions and ensure the stability of the plating solution.

Links: