Titanium anode products for oxygen evolution have excellent performance, long service life, stable mechanical properties, and can be processed into any shape. The mixed metal oxide (MMO) coating of Sanneng titanium anodes for oxygen evolution processes has helped many industrial electrolysis processes and technologies achieve rapid development while improving product quality.

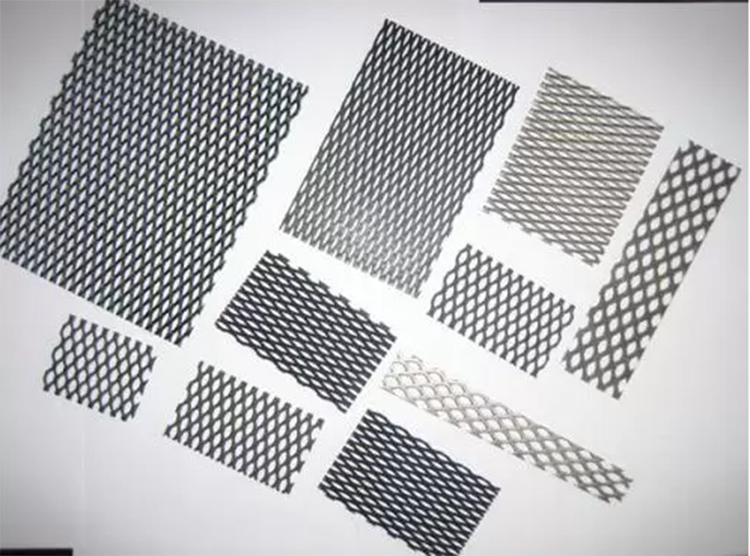

Sanneng Titanium Anode has developed a variety of anode structures over the years to meet the needs of various industries. Today, we produce anodes in various shapes: sheet, mesh, rod, strip, plate, wire, tube or combined shapes. Dimensions vary from cm² to m². The process of using the anode determines its size, shape and coating specifications.

From the chlor-alkali production industry to water disinfection and water treatment applications, anodes are a key part of technological innovation in these fields.

On the basis of the original oxide-coated metal anode concept, "Qixin Titanium" was further developed to test the coating combination of different new elements to create a variety of mixed metal oxide coatings with different characteristics and properties, which are applied to Industrial sector.

The launch of Sanneng titanium anode has not only completely changed the electrode industry, but also changed the electrolysis process. Without the titanium anode, the ion exchange membrane process cannot be completed. Today, titanium electrodes have been widely used in diaphragm technology and ion membrane technology. Whether it is anode, cathode structure, or zero-distance technology, it has been improved to the greatest extent because of the innovation of titanium anode technology.

Application of chlorine evolution anode

· Chlor-alkali production

· Water disinfection treatment

· Diaphragm process

· Ion membrane process

Links: