The casting process of titanium and titanium alloys includes several tempering periods, and each tempering period can choose the method of fire, wet or electric casting of titanium alloys. Therefore, each tempering period is generally referred to as the process of casting titanium alloys. For example, blast furnace ironmaking is the process of fire casting titanium alloy, zinc calcination is the process of wet casting titanium alloy, and purification liquid electrowinning is the process of electrochemical casting titanium alloy. The process of casting titanium alloy can be divided into many unit processes. Such as drying of ores or concentrates, pelletizing or agglomeration, roasting, roasting (including terbiumization, recovery, magnetization, ironization and other roasting processes), sintering, recovery smelting (including solid carbon, hydrogen, carbon monoxide, metal thermal recovery and other processes), matte smelting, gasification and blowing, pyrolysis, leaching or dissolution, purification of leachate, flocculation of pulp, sedimentation and clarification, concentration or concentration, filtration, scrubbing, crystallization, ion exchange, casting titanium Alloy, gasification casting titanium alloy, Chengqi casting titanium alloy, vacuum casting titanium alloy, distillation and transpiration, fuming, aqueous solution electrolysis, molten salt electrolysis, metal casting, etc.

It should be mentioned that the technical process of casting titanium alloy engineering, in addition to obtaining purified metal, also asks questions about the four collections of associated valuable metals, the management and comprehensive utilization of three wastes (exhaust gas, waste slag, waste liquid) and so on. Therefore, the complete technical process is very complex, and the process of casting titanium alloys is also many.

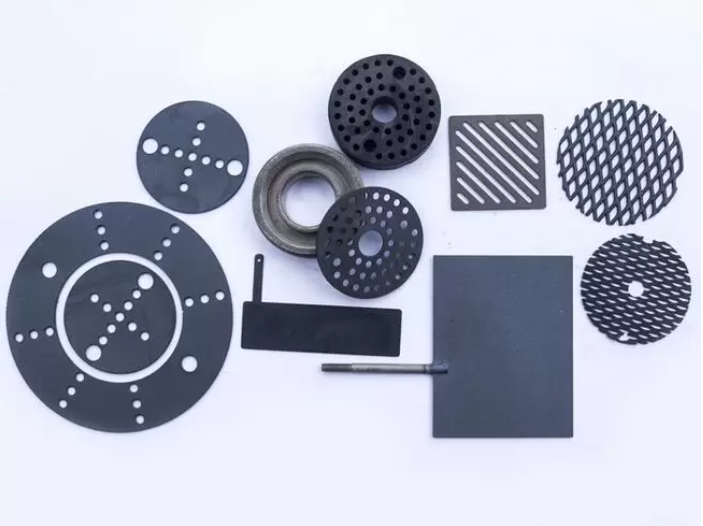

Due to the complexity of the engineering composition of casting titanium alloys, the casting titanium alloy equipment used is also various, such as blast furnaces, sintering machines, jubilant furnaces, flash furnaces, furnaces, rotary kilns, reflection furnaces in pyro-casting titanium alloys Furnace, blast furnace, electric furnace, refining equipment outside the furnace, etc., various forms of electrolytic cells and various reactors in wet casting titanium alloys. In addition, there are dust collection equipment and liquid-solid separation equipment. The selection of the use of these equipment also determines the role of the process of casting titanium alloys, and is the key to the success of the production of suitable titanium alloys.

Foundry titanium and titanium alloy industry refers to the industrial sector of exploration, mining, selection, refining and rolling of metal deposits, including black cast titanium alloy industry (ie titanium plate industry) and non-ferrous cast titanium alloy industry. Foundry titanium alloy industry is an important raw material industry sector, supplying metal materials for various sectors of the national economy, and also the material basis for the economic development of cast titanium alloy engineering. Obtaining and purifying metals from ores or concentrates cannot be accomplished in one step, and must be divided into several periods to complete, but the training methods and equipment used in each period are different. The casting titanium alloy project systematically connects the various periods, which constitutes the technical process of the training of a certain metal. If the skill flow is represented by a schematic diagram, it is called a skill flow diagram. A complete titanium plate production line can be divided into: coking, sintering pellets, iron making, titanium smelting, continuous casting, titanium rolling, etc.

Links: